NWA Industrial Maintenance Training — Upskill Your Workforce at No Cost

Arkansas manufacturers and facilities face a growing demand for skilled maintenance technicians. NWTI in Springdale, Arkansas, is offering no-cost training in Basic Electricity and Motor Controls to help industry partners upskill entry-level employees, support new hires, or develop future talent. These hands-on, instructor-led courses are fully grant-funded for a limited time and aligned with the real-world needs of today’s industrial environments.

Whether you're looking to strengthen your internal workforce or refer job-seekers for pre-employment training, this is a high-impact opportunity with no tuition cost to you or the participant.

Act Now!

Our Courses

Basic Electricity I:

This four-day class provides an introduction to the fundamental principles of electricity for industrial applications. Topics covered include electrical fundamentals, Ohm’s Law, direct and alternating current, series, and parallel circuits, magnetism, and motor basics. Students will explore key electrical components, such as transformers and branch circuits, and will develop basic troubleshooting skills for electrical systems. Through hands-on exercises and theoretical knowledge, participants will learn essential techniques to safely and effectively work with electrical systems in an industrial environment.

We designed this course for individuals new to industrial maintenance or those needing to refresh their basic electrical concepts.

Basic Electricity II:

This four-day class expands on fundamental electrical concepts, focusing on practical applications in industrial systems. Key topics include ladder diagrams, alarm circuits, motor starter controls, troubleshooting techniques, and auto defrost cycles. Participants will gain hands-on experience with electrical circuit analysis, control devices, and troubleshooting methods for industrial equipment. The course also covers advanced topics such as compressor circuit analysis and the use of 4-20 mA signals in process automation.

This course is ideal for those seeking to deepen their understanding of electrical control systems in industrial settings.

Motor Controls:

This 4-day training course provides an in-depth, hands-on introduction to motor control systems used in industrial and commercial applications. Designed for maintenance personnel, electricians, and technical students, the course focuses on the operation, wiring, and troubleshooting of motor starters, relays, overloads, and control circuits. Participants will learn to interpret motor control schematics, build functional circuits, and apply proper safety procedures while working with energized equipment.

Through guided lab activities and real-world scenarios, students will gain practical motor control design, installation, and fault diagnosis skills—including reversing starters, jogging circuits, interlocks, and Variable Frequency Drives.

Where you'll train:

NWTI Industrial Maintenance & Ammonia Refrigeration Technology (IMART) Building

Springdale, AR

Where to fly:

Northwest Arkansas National Airport (XNA)

Bentonville, AR

Where to stay:

Holiday Inn Springdale/Fayetteville Area

1500 South 48th Street, Springdale, AR

(479)601-8450

BOOK NOW

Home2 Suites by Hilton Springdale

1519 S. 48th St. Springdale, AR 72762

BOOK NOW

Hampton Inn & Suites Springdale

1700 S. 48th Street Springdale, AR 72762

BOOK NOW

Hyatt Place Fayetteville/Springdale

348 East Van Asche, Fayetteville, AR 72703

(479)756-6101

BOOK NOW

Fairfield Inn & Suites Fayetteville

755 Van Asche Dr, Fayetteville, AR 72703

479-551-9270

BOOK NOW

When you'll train:

Basic Electrical I (Four Day Course)

July 7-10, 2025

Basic Electrical II (Four Day Course)

July 14-17, 2025

Motor Controls (Four Day Course)

July 21-24, 2025

Employees can finish crucial IMART training in a week with flexible, modular courses designed to accommodate individual skill levels and paces. Training options are stackable, ensuring a seamless path for continuous skill development.

How to register:

Register your employees for available courses today!

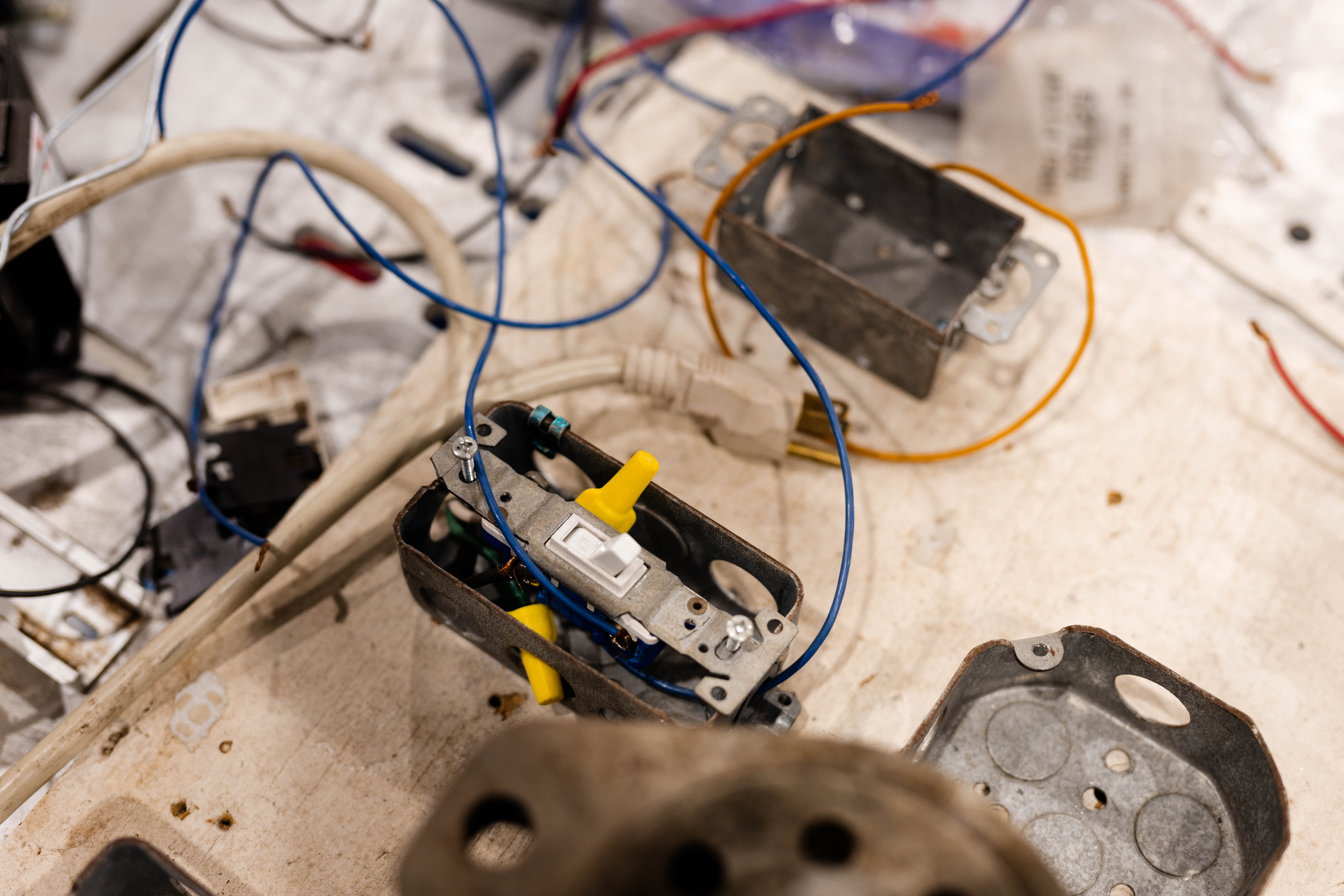

Our Equipment

Students train on various industry-grade equipment, ensuring they gain experience with the same advanced systems used in the field. From control systems to hydraulic, pneumatic, and electrical troubleshooting tools, our training environment mirrors real-world industrial settings, giving participants the confidence and technical skills to excel on the job.

COMING SOON: A virtual tour of our entire Industrial Maintenance facility!

Our Instructor

Customized Industry Training:

In addition to Industrial Maintenance courses, NWTI offers a wide variety of flexible, high-quality training designed for your workforce. These include, but are not limited to:

Ammonia Refrigeration - Theory of refrigeration and related subjects provides an understanding of the task-oriented topics and activities experienced in the industrial, commercial, or private sector..

Welding & Fabrication – Practical training in welding techniques, blueprint reading, and metal fabrication.

HVAC & Electrical Systems – Training on heating, ventilation, air conditioning, and electrical troubleshooting.

Commercial Truck Driving (CDL) – Professional driver training to meet regional and national transportation needs.

Electronics & Automation – Robotics, automation, and process control for modern manufacturing environments.

Workplace Safety & Compliance – OSHA, HAZMAT, and other essential safety certifications.

Let NWTI help you build a stronger workforce. Contact us today to develop a training program customized to your needs.